Bruker is continuously driven to provide the best technological solution for every analytical task. We understand how critically important the correct Metal Identification and Alloy Identification is to a wide range of industries - this is why we have developed our state-of-the-art metal testing tools.

Step Up Your Scrap Metal Testing with the Bruker Alloy Tester

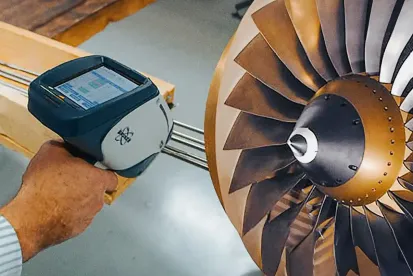

Bruker's Handheld and portable XRF analyzers allow for rapid metal identification, engineered for ease of use, accuracy, and reliable elemental analysis. See where fit, form, and function all intersect with our metal sorting instruments. Designed for the most demanding customer applications, our rock-solid analytical tools are a fast, precise, non-destructive solution for alloy identification.

The Bruker S5 TITAN portable XRF analyzer makes metal analysis easier than ever before. A lightweight, mobile alloy analyzer that leads the way in performing crucial tasks in the alloy industries.

Designed for use in nearly any weather condition, field environment, and location, the S5 TITAN will give you reliable results in seconds. The use of a Bruker metal tester saves significant expenses in comparison with traditional laboratory testing. With shorter measurement times and superior detection limits, our handheld XRF analyzers increases your productivity. For our thousands of customers around the world, a Bruker metal analyzer offers a high profit potential and low long-term ownership costs.

Typical XRF Analysis Applications for the Metal Tester Guns

Our metal indentifcation tools are designed for use in a wide array of applications from sorting, research & development and production where testing can be used to verify quality and determine process reliability.

Typical XRF analysis applications include:

Learn more about the different XRF applications of our metal identification tools and dive deeper into how PMI Testing works!

Contact form

Industries we influence

Bruker has made it its mission to help as many relevant industries as possible with its metal identification tools. We influence many powerful industries:

Metallurgy

Aerospace

Scrap and Recycling

Food Processing

Plumbing

Petrochemicals

Find out how we can solve the biggest challenges in your industry segment:

Bruker Nano Analytics US

5465 E Cheryl Pkwy

Madison WI 53711

Phone:+1-509-736-2999

Bruker Nano Analytics DE

Am Studio 2D

12489 Berlin

Email:info.bna@bruker.com