Discover the power of Bruker’s handheld XRF copper testing machines, designed to cater to a diverse range of needs: From copper purity testing, copper scrap sorting to intricate tests for trace amounts of copper in ores.

Copper, a vital element in many industries due to its exceptional conductivity and malleability, plays a crucial role in sectors like electronics, construction, and manufacturing. Accurate copper analysis is essential to ensure the quality and composition of materials, and to meet industry standards and regulations.

With our advanced technology, you can swiftly and reliably test copper purity and assess copper content, whether you're involved in copper mining, copper alloy fabrication, scrap recycling, or environmental assessment. Gain a deeper understanding of the copper content in your samples, optimize your operations, and maintain an efficient and productive workflow by harnessing the capabilities of Bruker’s handheld XRF copper analyzers.

Copper Analysis with Bruker Handheld Non-Destructive Analyzers

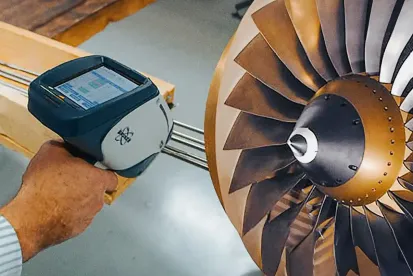

Our portable copper analyzer the Bruker S1 TITAN is an advanced tool for the precise measurement of copper (Cu) in a sample without causing any damage. Handheld copper testers can be used to analyze a sample's compostion, providing precise elemental results. They can detect trace amounts of copper, determining copper content up to 100%. Handheld XRF copper analyzers are useful in a range of scenarios:

Copper Alloy Grade Identification: They help identify various copper alloy grades.

Historic Copper Alloy Analysis: Copper testers are invaluable for studying historical artifacts or objects made from copper alloys.

Copper Plumbing Compliance: In plumbing, copper is commonly used. Bruker‘s copper analyzer helps ensure copper meets required standards, guaranteeing the quality and safety of plumbing systems.

Determine the Elemental Composition of Any Copper Alloy

When it comes to determining and analyzing different copper alloy compositions, Bruker offers a reliable and non-destructive way using its advanced handheld XRF copper analyzers. These devices are designed to provide you with accurate insights into the elemental composition of different copper alloys like the following applications:

Brass Grade Identification: Precisely differentiate between various brass compositions for quality control, manufacturing, or research purposes using our handheld copper analyzers.

Bronze Grade Identification: Accurately identify and analyze different bronze grades.

Copper-Nickel Alloy Grade Identification: Empower industries with optimal performance, from marine to electronics, with the ability to identify and understand copper-nickel alloy compositions.

Historic Bronze and Brass Analysis: Delve into the chemistry of historical bronze and brass artifacts with our copper testers, providing non-destructive results for archaeologists, historians, and conservators.

Test Copper Purity at Home: Explore our range of handheld XRF analyzers for testing copper purity at home.

Bruker offers a range of handheld XRF copper testers tailored to various requirements.

Contact form

Bruker Nano Analytics US

5465 E Cheryl Pkwy

Madison WI 53711

Phone:+1-509-736-2999

Bruker Nano Analytics DE

Am Studio 2D

12489 Berlin

Email:info.bna@bruker.com